Energy

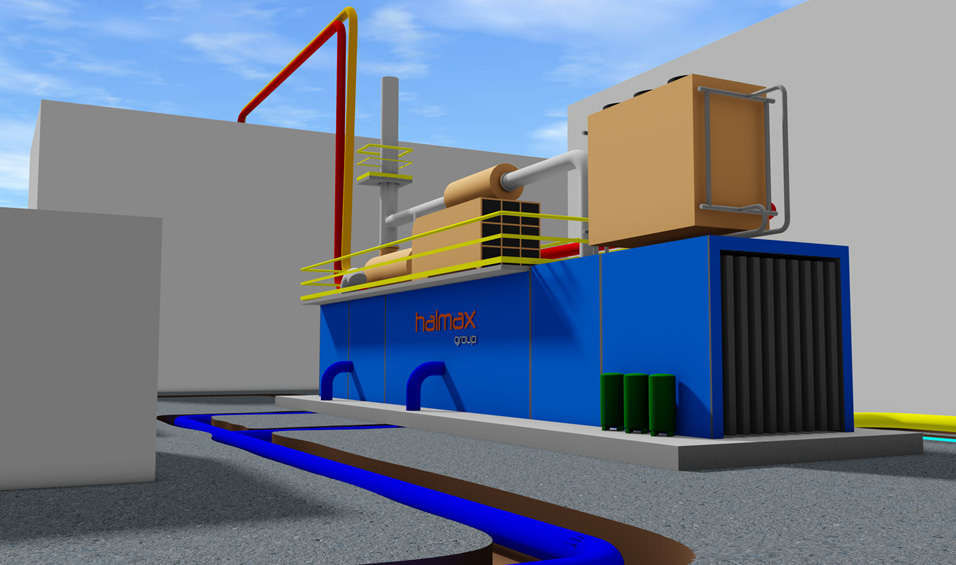

Halmax Group can boast a long experience in the energy field and cogeneration plants. A constant growth along these years has been the key for collaborations with the most important companies dealing in this field.

The company has developed and improved endothermic motors technology achieving cogeneration plants for industry and little urban communities with a range of power from 200 kW up to 4MW.

Halmax Group has optimized a biomass plant by recovery boiler based on fluidized bed gasifier, in order to improve the power system efficiency.

HIGH EFFICIENCY COMBUSTION OF MICRO-TURBINE

Cogeneration by Micro-Turbine is an new advanced system ables to produce both Electric and Thermal Power with high efficiency by means of recycling of thermal power.

This can be reached by replacing the old one with a new generation of high efficiency burner capable to modulate the process steam production. This new technology can remarkable increase the efficiency of common Power Generator up to 98%. This leads to lower cost for fueling and lower emissions of polluting gas than traditional plant in addition to a fewer maintenance activities.

A wide range of turbines are compatible with the Cogeneration System achieving high efficiency Energy production from any point of view. The power range comes from 1 MW up to 20 MW achievable by boiler which are powered by gas, biogas, oil and so forth.

Basically, cogeneration plant consists of a little gas turbine and a Boiler housed inside of soundproof cabin. In these systems, the gas turbine generates both the Electrical Power and an hot exhaust gas conveyed in the boiler for generating the process steam. An additional burner in the Boiler is adopted for the steam supply modulation. The Electrical Power can be utilized for supplying the plant or can be poured into the net.

Part of the steam flow rate coming from the boiler can be used to supply an additional steam turbine if an extreme flexibility of process steam is required or employed for heating or for getting hot water. In such case Gas turbine and Boiler can independently operate but the best efficiency is reached when they work together getting very low environmental impact. The mean plant lifetime is of 80000 hours.

Plants conceived only for Thermal Power production are – today – a very low efficiency concept. By Adding a Micro turbine system and employing a new generation of Burners is possible to produce of both the cheapest Electrical Power and Process Steam production. This leads to get a very short payback times ranging from 18 to 36 months (max).

Halmax Group can design and realize customized solutions compatible to any kind of plant and process necessities, satisfying in this way all customer expectations in term of cost saving, plant efficiency and payback time.

|

|

|

|